-

R&D Strength

-

Green Intelligent Factory

-

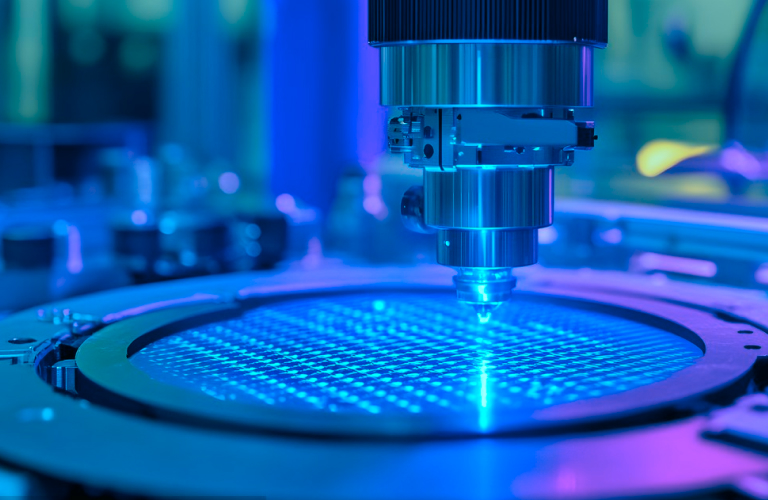

Intelligent Manufacturing

-

Quality Management

R&D Strength

Self-developed MEMS Die & ASIC, vehicle-mounted RNC/A2B/ANC products, and intelligent voice call modules, etc., are in a leading position in the industry and have achieved large-scale

-

01Product Innovation Capability & New Product Form Exploration Capability

The Industry's first Button Microphone, high wind-blast resistant MEMS Microphone; Electret Microphone, a national manufacturing single champion product; MEMS SPK, dual voice coil driver, screen sound-emitting unit, etc.

-

02The product research and development capabilities

Self-developed MEMS Die & ASIC, vehicle-mounted RNC/A2B/ANC products, and intelligent voice call modules, etc., are in a leading position in the industry and have achieved large-scale

-

03Professional Technical Team

We have a professional R&D team of more than 100 people, of which more than half have the capability of independent product development for over 10 years.

-

04Acoustic Testing Capabilities & Software & Tooling Development Capabilities

BK Pulse 3560C testing system 600㎡ professional anechoic chamber (background noise: 18dBA) CAT & MAT production testing software platform & modular testing tooling

-

05Design and Simulation Capabilities

Software such as Multisim, ANSYS, Micro-Cap, and Pro/E can be used for circuit, mechanical, acoustic, and structural simulations, etc.

-

06Collaboration between Higher Education Institutions and Organizations

We have in-depth cooperation with a number of domestic colleges, universities and national acoustic research institutions, providing rapid technical response.

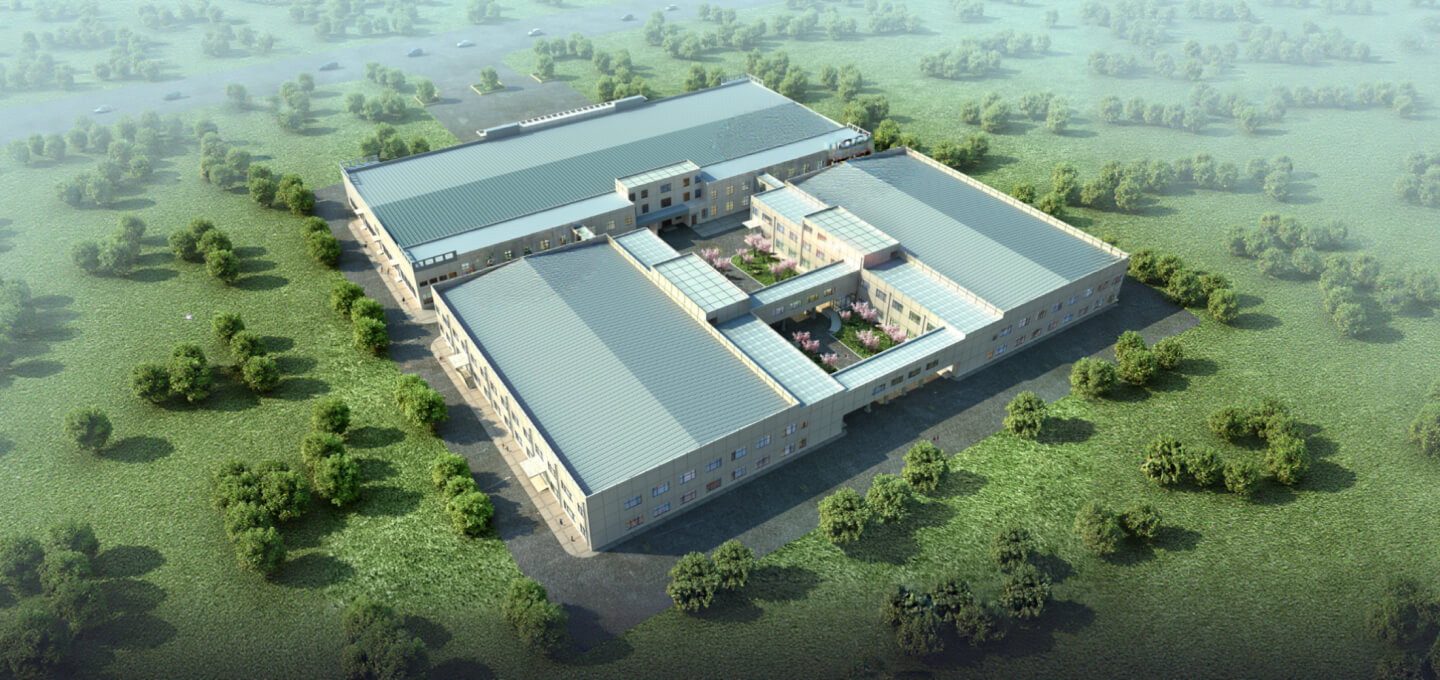

Green Intelligent Factory

Creating a sustainable intelligent manufacturing factory

-

Gettop Acoustics Phase I Factory

Gettop Acoustics Phase I Factory-

Location: Weifang, Shandong

-

Area: 170 mu (approximately 113,333 square meters)

-

Main Products: Microphones, microphone components, vehicle-mounted products

-

-

Gettop Acoustics Phase II Factory

Gettop Acoustics Phase II Factory-

Location: Weifang, Shandong

-

Area: 260 mu (approximately 173,333 square meters)

-

Main Products: Speakers, receivers, structural parts

-

-

Gettop Acoustics Malaysia Factory

Gettop Acoustics Malaysia Factory-

Location: Johor, Malaysia

-

Area: 7,500 square meters

-

Main Products:Microphone components、Automotive products

-

-

Gettop Zhejiang Factory

Gettop Zhejiang Factory-

Location: Yiwu, Zhejiang

-

Area: 50 mu (approximately 33,333 square meters)

-

Main Products: Mobile phone speakers, automotive speakers, structural components

-

Intelligent Manufacturing

We provide custom-made product components and intelligent acoustic solutions tailored to customer needs, along with services covering the entire design process. This forms a complete service chain including required function analysis, performance design, application technology matching, full-process R&D support, prototype production and testing

-

Consumer/IoT-ECM Intelligent Manufacturing

Consumer/IoT-ECM Intelligent Manufacturing-

99%Automation Rate

-

420 Million (pieces)Annual Production Capacity(pieces)

-

SMT (Surface Mount Technology)

-

Monomer assembly automation

-

Performance testing automation

-

Product packaging automation

-

Product welding automation

-

-

Consumer/IoT-MEMS Intelligent Production

Consumer/IoT-MEMS Intelligent Production-

100%Automation Rate

-

1 BillionAnnual Production Capacity(pieces)

-

Wafer Dicing

-

DB、WB、CT

-

Shell Mounting, Testing

-

Film Laminating, Packaging

-

-

Consumer/IoT-SR Intelligent Production

Consumer/IoT-SR Intelligent Production-

99%Automation Rate

-

110 MillionAnnual Production Capacity(pieces)

-

Unit standardization, enabling quick changeover

-

Diaphragm assembly automation

-

Monomer assembly automation

-

Product packaging automation

-

CCD inspection automation

-

Performance testing automation

-

-

Consumer/IoT-Module Intelligent Manufacturing

Consumer/IoT-Module Intelligent Manufacturing-

120 MillionAnnual Production Capacity(pieces)

-

Production lines for MEMS components, etc.: 6 lines

-

Customized adhesive mounting and automated assembly lines

-

SMT automation, AOI inspection, SPI

-

FPC bending automation and assembly capability

-

ECM full-automation welding

-

-

Automotive, PCBA, and Complete Machine Intelligent Manufacturing

Automotive, PCBA, and Complete Machine Intelligent Manufacturing-

10PCBA Complete Machine Production Lines (Unit: Line)

-

23Automotive Production Lines (Unit: Line)

-

100 MillionAnnual Production Capacity(pieces)

-

Automated Production Lines

-

Automatic Welding

-

Automatic Labeling

-

Automatic Screw Driving & Gluing

-

Laser Welding

-

Visual Inspection

-

-

SPK BOX Intelligent Manufacturing

SPK BOX Intelligent Manufacturing-

10BOX Automatic Assembly Lines (Unit: Line)

-

100 MillionAnnual Production Capacity(pieces)

-

Assembly Automation

-

Solder Joint AOI Inspection

-

Performance Testing Automation

-

Vision-Guided Adhesion of Die-Cut Auxiliary Materials

-

RFID Chip for Glue Open-Time Control

-

Quality Management

The company implements the "Three Standardizations and One Stability" model, supported by a quality management system framework, to carry out full-process management and all-round quality control. Guided by customer needs, it pursues continuous improvement to enhance product quality levels.

-

01Design and Development

New Product Quality Monitoring:

DQA: Review, identification and verification of customer requirements; communication and implementation of customer standards.

DQA: Access management at each stage.

DQA: Reliability verification of new products, as well as full-dimension, full-performance inspection and margin analysis.

DQA: Management of new product production processes & sample delivery inspection, and planning for strict incoming/outgoing control of material and product standards.

SQA: Supplier material qualification (alignment, execution and implementation of standards and reliability rules).

-

02Product Manufacturing

Mass Production Quality Monitoring:

PQA: Qualification management for transfer to mass production and newly set-up production lines.

PQA: Product flow management and strict incoming/outgoing control in the first three months after transfer to mass production.

PQA: Inspection and control of process procedures (CTQ/ORT/warning values).

PQA: Management of detection rates for testing equipment and inspectors.

PQA: Continuous process audits and anomaly management; dynamic management of OQC inspection sampling.

PQA: Quality improvement for key projects (QCC & 6Sigma).

SQA: Monitoring of suppliers' process capability, incoming material inspection, and reliability monitoring.

-

03Customer Service

Customer Quality Assurance:

CQA: Rapid response to the voices of customers and factories, including follow-up and on-site communication.

CQA: Alignment for the overall improvement, audit and continuous enhancement of internal project quality.

CQA: Formulation and assessment of project quality performance and performance rules.